On April 9, 2023, the release of the 5thCutting Tool User Survey Results Release and the award ceremony of the 3rdCutting Tool Product Innovation Award of "Jin FengAward" was held in Beijing Kuntai Hotel. Chengdu Bangpu Cutting ToolsCo., Ltd won both the "Most PotentialBrand" and "Jin Feng Award"!

TheMost Potential Brand in the 5th Cutting Tool User Survey

The"Cutting Tool User Survey" is organized by the Metal ProcessingMagazine of the Mechanical Industry Information ResearchInstitute. It has been successfully held four times in 2002, 2008, 2014,and 2019. It has caused a huge wave in the cutting tool industry and played animportant guiding role for tool producers and users. This survey is recognizedas a very authoritative, highly concerned, and trusted industry survey inChina's cutting tool industry.

"JinFeng Award" The 3rd Cutting Tool Product Innovation Award

The"Jin Feng Award" is an award established by the Metal ProcessingMagazine of the Machinery Industry Information Research Institute to encourageenterprises for product innovation. The product range includes machines,machining centers, cutting tools, functional components, CNC systems, metalprocessing oils, etc.

"JinFeng Award", the cutting tool product innovation award was launched forthe first time in 2019 and is held every two years. Each selection has attracted widespreadattention from the industry, and it is the pinnacle platform for innovativecutting tool products to show themselves and drive the lead. Award-winning products have always beenhighly recognized and fully affirmed by the industry.

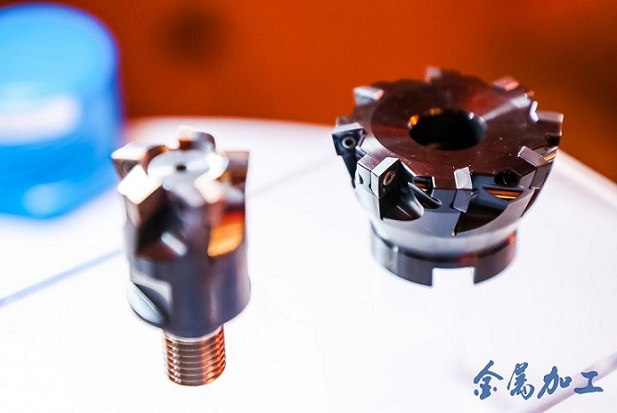

Theselection of the 3rd cutting tool product innovation award of "Jin FengAward" was launched in February 2023. After preliminary screening,publicity, and review, 63 products from 40 domestic and foreign cutting toolcompanies entered the online selection, expert review, and editorial review.Strict evaluation rules ensure fairness, impartiality, professionalism, andauthority to the greatest extent. Finally, the top 15 innovative tool productsat home and abroad with comprehensive scores were selected, and the"high-performance high-feed milling tool" from Chengdu Bangpuis one of them.

Award-winning Product Introduction:

Technologicalinnovation point 1: A blade slot that takes into accountboth practicality and safety. The P110 series high-feed milling cutter isdesigned with an insert slot on the cutter body. When installing the blade,first put the non-cutting edge into the slot, and then lock it with screws. Onthe one hand, it ensures the stability of the blade during processing; on theother hand, it can ensure that the blade will not splash out and hurt theworkpiece, machine tool or personnel when it is abnormally damaged.

Technologicalinnovation point 2:Blade edge surface curved design. Onthe one hand, it ensures the maximum removal of processed materials, therebyimproving processing efficiency; On the other hand, it can also achieve highersurface finish during rough machining. We accumulated rich application datathrough a large number of experiments and finally determined the arc of theblade edge, which can achieve the maximum single tooth feed of 2mm.

Technologicalinnovation point 3: Latest materials and coatings. Toensure the reliability and durability of the high-feed milling cutter, we havedeveloped the latest composite substrate and NACO3 "crystal feather"coating for the inserts in combination with the application conditions. It is acoating specially developed for HRSA (heat-resistantsuper alloy) with low thermal conductivity and serious problem of workhardening. The combination of the two balances the toughness and wearresistance, and the processing speed can be increased to 70m/min, which greatlyimproves the tool life and processing efficiency.

Technologicalinnovation point 4: Extremely thin chips. The thicknessof the chip depends on the main deviation angle of the tool. When the singletooth feed rate of the traditional milling cutter is 0.2mm/z, the chipthickness is 0.2mm. The P110 series high feed milling cutter uses self-designeddeviation angles to perfectly match the inserts. When the chip thickness isalso 0.2mm, the single tooth feed rate can reach 1.4mm/z, and the cycle time isgenerally reduced by 50% or more.

This honor represents the recognition of Bangpu cuttingtools by the majority of cutting tool users. Bangpu tools will continue toimprove its own strength, launch products with higher performance, and provideusers with better services.