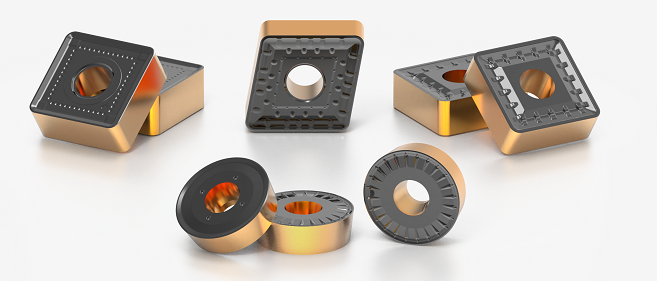

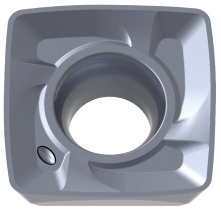

New Steel Turning inserts - "Precious Jade" Series Products with grades BP6315 and BP6225.BP6315 is more suitable for high-speed continuous processing and is the preferred material for general steel parts processing, with excellent resistance to thermal cracking and plastic deformation. BP6225 is more suitable for interrupt machining and is the preferred material for medium and rough machining of steel parts. Its strong toughness-resistant matrix is combined with the heat-resistant AL203 coating.

READ MORE

The special arc design of the blade edge effectively reduces cutting resistance during fast feed machining; The cutter head adopts a special cutting angle design and explosion-proof slot, which is more stable and improves its lifespan; At the same time, replacing the original integral milling cutter with a threaded cutter head and an extension rod can reduce subsequent costs and fully meet customer processing needs

READ MORE

AL open chip breaking groove. Suitable for precision and medium turning of non-ferrous metals such as aluminum and copper parts. The recommended grade is BU810. The excellent groove design makes chip control and chip flow smoother, effectively reducing cutting resistance and extending tool cutting life. TF3 is closed chip-breaking groove. Suitable for finishing non-ferrous metals such as aluminum and copper parts, with a cutting depth range of 0.2-0.5mm.

READ MORE

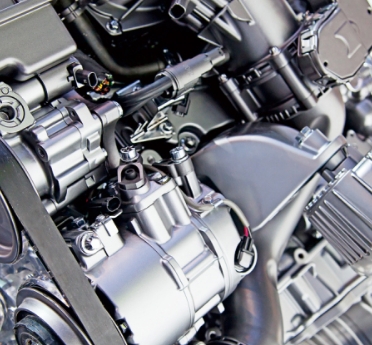

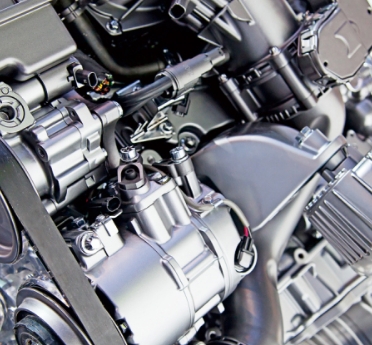

The heavy-duty turning inserts adopt self-developed high-toughness substrates, specially designed grooves, and new MTCVD coatings, specifically designed for medium and heavy rough machining in industries such as wind power, mining, and wheels. Heavy load cutting belongs to rough machining, and in order to improve cutting efficiency, it is necessary to increase the feed appropriately. According to different processed materials and working conditions, chip-breaker RM, RX, RH are designed. RM:Vc80-260m/min,Fn0.40-0.80mm/r,Ap8-15mm RX:Vc80-260m/min,Fn0.50-0.90mm/r,Ap9-16mm RH:Vc80-260m/min,Fn0.60-0.10mm/r,Ap10-18mm RS:Vc80-260m/min,Fn0.90-1.50mm/r,Ap15-22mm

READ MORE

The inserts for heat-resistant super alloy has self-developed specialized grooves, special substrate formulas, and the latest PVD coating NACO3 technology, which can achieve more excellent performance and surface quality in medium and finishing machining of HRSA materials such as high-temperature alloys. Recommended chipbreaker for finishing is SL, TF3. Recommended for medium cutting is MS3 and MS6. Recommended cutting speed:20-50m/min.

READ MORETurning--Fine grinding turning tool for small cutting depth and chip breaking

Turning--Fine grinding turning tool for small cutting depth and chip breaking

READ MOREMilling--Double-sided round milling inserts with high metal removal rate

Milling--Double-sided round milling inserts with high metal removal rate

READ MOREMilling--High-speed aluminum milling inserts

Milling--High-speed aluminum milling inserts

READ MOREMilling--Fast feed milling inserts for heat-resistant super alloys

Milling--Fast feed milling inserts for heat-resistant super alloys

READ MORE

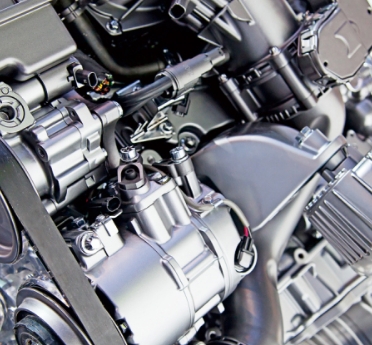

Chengdu Bangpu Cutting Tools Co., LTD. (hereinafter referred to as "Bangpu"), is a high-tech enterprise that has been deeply engaged in the CNC cutting tools industry for 22 years. At the beginning of its establishment in 2000, Bangpu's sales increased by 124% in three years and it became one of the top 500 companies in Asia Pacific with high growth. 。

China: +86-028-66337598

Overseas: +86-028-66337597

Zip code:611731

ADD: No. 998 Baicao Road, Gaoxin West District, Chengdu (formerly No. 16-1)